The Coking.com team has performed onsite field work at more than 80 Delayed Cokers around the world. The team has interacted with nearly all of the cokers in some fashion. As such, they are in a unique position to comment on best practices in the industry. Our motto is “Don’t let best get in the way of better practices.” There are many ways to solve a problem from no cost to low cost and finally high cost with varying degrees of resolution. The team initially focuses on no or low cost solutions to problems based on common sense and first hand field experience. If engineered solutions are required, the team can provide that expertise as well.

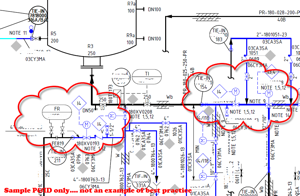

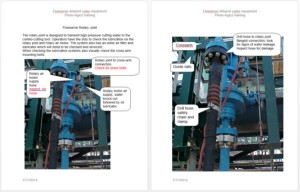

An example, delayed coker structure steam purged valves are notoriously unreliable due to steam purge issues. It is well known to all the vendors and users of these valves that steam purge must be dry and constantly above process pressure. If the valves are unreliable, simple improvements to the steam system piping and control system have been shown to increase reliability substantially for little or no cost. Increased operator oversight can be equally as effective. The next step would be develop a more reliable steam source, high pressure steam letdown is the obvious choice. Working with plants, the team has seen mean time between failures rise from 1-2 years to easily making the turnaround target or 5-6 years.

The typical repair for a SP valve may require at minimum a short bypass or a full shutdown for some period of time, significant removal and installation costs (ex. large crane) direct repair costs, and the safety risks associated with this type of job. These costs can run $300k to $1M+. The team can help you prevent this type of cost through tried and true best practices learned from plants of all configurations.

Contact Coking.com and Refining Community.

Learn more about

Coking field services, consulting and training

Coker Best Practices and Lessons Learned

Best Practices for Coker Operations

Best Practices for Coker Maintenance

Best Practices for Coker Design

Training for Delayed Coking Engineer

Training for Coker Maintenance

Coker Industry Lessons Learned

Cold Eyes review of coker equipment, projects, procedures and operations

Process Hazard Analysis (PHA) and HAZOP Subject Matter Experts for Delayed Coker

Coker startup and commissioning support

Coker Turnaround / Shutdown Support

Troubleshooting your coker

Incident Investigation Subject Matter Experts