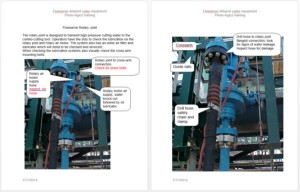

Operators are the first and last line of defense in the unit. Yet, they can often be overlooked as valuable way to optimize the unit. We differentiate ourselves from other consultants by taking the time in the unit to consider the operators perspective and experience the unit firsthand. By integrating the site specific learnings with other similar plants, we can provide tailored solutions to improve operator performance.

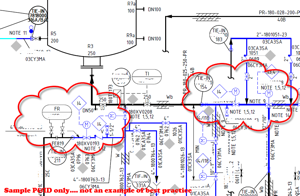

An example is coke drum Lock-out, Tag-out(LOTO). Recently, the coking industry has been driving toward interlocks and automation of the drum switching process. However, many old plants can not justify this expense. However, improvements in the procedure and LOTO of the drum can go a long way to prevent operator error by moving the wrong valve at the wrong time. Some of our most serious incidents (injuries and deaths) have resulted from such scenarios. We have worked with sites to improve and streamline this process whether their system is completely manual or even if they have state of the art interlock controls.

If you are interested in improving your operations practices with our help, please contact us.

@CokingCom #refcomm

Learn more about

Coking field services, consulting and training

Coker Best Practices and Lessons Learned

Best Practices for Coker Operations

Best Practices for Coker Maintenance

Best Practices for Coker Design

Training for Delayed Coking Engineer

Training for Coker Maintenance

Coker Industry Lessons Learned

Cold Eyes review of coker equipment, projects, procedures and operations

Process Hazard Analysis (PHA) and HAZOP Subject Matter Experts for Delayed Coker

Coker startup and commissioning support

Coker Turnaround / Shutdown Support

Troubleshooting your coker

Incident Investigation Subject Matter Experts