FREE

![]() Facilitator: Evan Hyde – REFCOMM®

Facilitator: Evan Hyde – REFCOMM®

Overview

Traveling the coking world, we have literally talked to 1000s of operators and opinions vary about the ‘best’ way to switch the drum and steam strip. In this installment of eREFCOMM, we are going to investigate the variety of techniques in place and discuss the pros and cons of various methods.

- Coke drum channeling

- Oil recovery

- Fractionator balancing

- Hot spot management

Webinar Recap

We at eREFCOMM hope that you enjoyed the interactive discussion on Coke Drum Stripping Steam! Here are some key takeaways from the event.

Coke drum steam stripping has many ripple effects and should be optimized. Given your current feedstocks and process conditions, we suggest that you do not simply assume what was in the procedure from the licensor is the best solution. Stripping has direct impacts on:

- Cycle time

- Valve reliability

- Quench water performance

- Coke drum life

- Hot coke eruptions

- Drain effectiveness

- Coke quality

- Coke carryover into the fractionator and blowdown

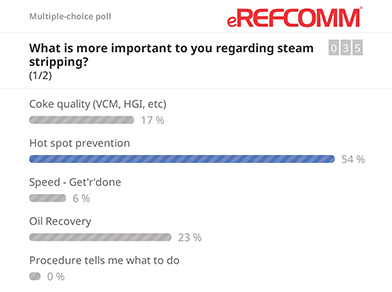

The live poll results, from today’s discussion, indicated that most respondents prioritized hot spot prevention as the primary goal of steam stripping. The secondary goals were nearly tied between coke quality and oil recovery.

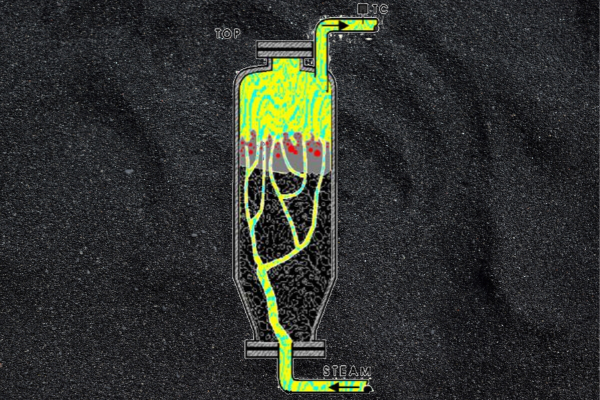

Some literature results of steam effects on coke bed formation were presented from the Penn State delayed coker pilot plant. These results showed the anticipated result that steam flow during bed formation creates large pores and more complex pores. Without steam, the bed was denser. What is not clear from this research if steam stripping can have a material impact on pore structure after the bed has formed. Additional research from the University of Tulsa was presented which showed how mass is removed from the top and middle of the coke bed during stripping. That research did not study the impact of variable steam stripping flows on the bed mass reduction, but it did show that antifoam effectiveness and bed formation effects, based on feed characteristics, can impact the effectiveness of steam stripping. Unsurprisingly, it all comes back to feed.

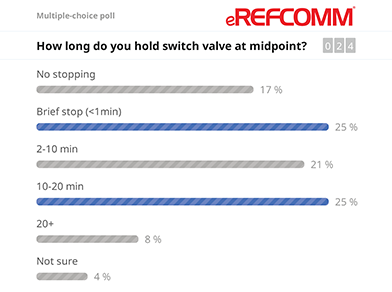

Steam stripping of the bed starts not just with the main flow of steam but before and during the switch. A poll showed that an equal number of respondents used a mid-point switch valve position hold of 10 – 20 minutes versus only a brief stop. This is consistent with our experience working directly with clients. We recommend a minimum hold to ensure good flow into the drum before proceeding to prevent the blocked-in condition. Holding longer can be positive for a variety of process reasons but can negatively impact switch valve reliability.

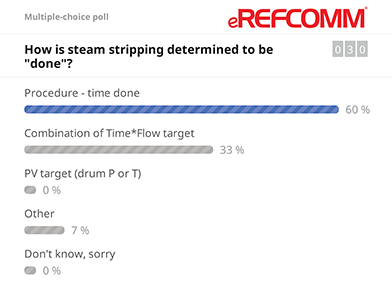

Determining when the stripping is complete is not easy and is a multivariable problem to solve. Most poll respondents indicated they use strictly a time-based approach. Hopefully, they are optimizing the time over time……

The ability to access the effectiveness of the stripping can have many parts. Below is a list of items to consider:

- Radial drum skin TI differences at various time/flow combinations

- Hot spots

- Coke quality, primary VCM

- Strainer cleaning frequency – fractionator and blowdown

- Pressure drop in drum vapor line accumulation slope

- Quench water effectiveness as measured by total quench water to the drum and the ratio of BD-sour water divided by total water input

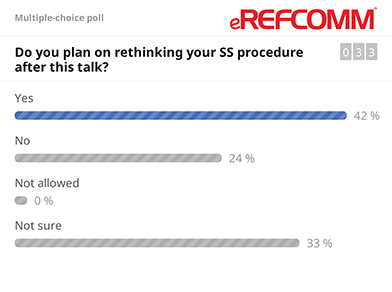

The final “live” poll asked if people are considering making changes to the steam stripping procedure based on this webinar….42% said yes and another 33% are not sure…. Therefore, if just a few plants make positive changes to impact all the downstream effects noted, then we have made a difference and that is what matters.

Questions from the Q&A

If the Heater trips momentarily, creating a potential for mixed morphology and/or hot spots, what is recommended for stripping steam flow rates?

From an attendee: Our procedure calls to keep a certain volume of emergency steam available, superheated at normal heater COT for at least 4 hours to blowdown prior to water quenching.

From Coking.com: It depends on the duration of the heater outage and whether or not cold resid was put into the drum. If cold resid was kept to a minimum and it occurred early in the cycle, the last effect should be minimal. However, if cold oil was fed into the drum and/or at the end of the cycle, you should consider an extended steam stripping (1 – 4 hours maybe) or even the SS stripping in severe cases.

How much time is recommended for the switch from frac to blowdown? 5minutes? Curious what other sites are doing or what is best practice.

From attendee: As long as possible but being careful to not upset the coke drum.

From Coking.com: Slowly, slowly… but the rule of thumb is 1 psig per minute. So, if the drums are 20 psig and the blowdown tower is 10 psig… then 10 minutes to swing into the blowdown. If you do it too quickly and depressure rapidly, then coke will likely be carried over into the vapor line and blowdown tower.

Thank you for everyone who participated! Come enjoy and participate in our next eRefComm event, “How Much Should You Quench Coke Drum Vapors?” – May 14, 2020.