Overview

Although often more extensive near the outlet flange of the valve body, cracks are found in a wide variety of locations in valves used to isolate the feed lines and the overhead vapor lines. Thermal cycles during the coking process often lead to body, bonnet and plug cracks. Without the proper NDE being performed and the hardness of prior weld repairs being checked (to ensure they were stress relieved properly) smaller cracks will grow, resulting in more costly and time consuming repairs that can lead to unnecessary down time on the unit.

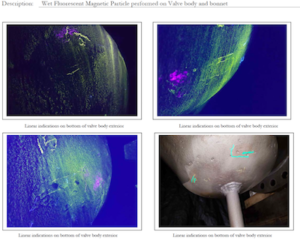

Small cracks that need to be addressed so that they do not become severe during the next 5 year run

According to Bay Valve Service & Engineering, LLC, the most effective process for crack repair involves the following steps:

- Perform 100% Magnetic Particle Examination on body, bonnet and plug.

- Hardness Testing of body, bonnet, and plug (w / special focus on any evidence of prior weld repairs)

- Provide the client with notification of any cracking found, along with the NDE reports.

- After client approval to proceed, excavate the crack by grinding along the crack and to the depth that the crack continues.

- Report the final depth to the customer and then proceed with a weld repair performed to ASME Section IX with the proper post weld stress relieving.

In fact, Bay Valve’s Benicia, CA Location just finished three largescale Wedgeplug DCU Turnarounds. Via extensive NDE inspections, the company identified significant body cracking in multiple valves of C12 material. After identifying all body and plug cracks, Bay Valve completed the necessary weld repairs and stress relieving while meeting all target delivery dates for repair completion. The company used Microsoft Project for the tracking of these repairs to ensure the clients were always aware of the timelines for the delivery for each individual valve.

Above: Large Cracks Creating Significant Challenges to return the valves to service

Along with over a million dollars invested in the equipment to precision grind & fit these valves, what sets Bay Valve apart from other companies is that many companies offer repair of these critical valves but do not perform in-depth inspections (including Wet Mag on these components). Instead many utilize only Dye Penetrant examination. Dye Penetrant is not an effective or thorough method of examining cast components which allow small cracks to be missed and therefore grow during the next period of operation. This can leave these cracks to later compromise the required body wall thickness. Severe cracks will either lead to severe repairs, possibly extending outage times, or the emergency replacement of a valve.

About Bay Valve Services

Bay Valve is a leading company in the repair of switch valves, wedgeplug or metal seated ball valves for Feed and Overhead Vapor Isolation, and Electric Actuation. Bay Valve Service has a team of people dedicated to the sizing, selection, and service of electric actuation. For those interested in learning more about Bay Valve, the company will be exhibiting at RefComm® Galveston 2018, where the company will focus on the repair of Overhead Vapor/Feed Isolation, and Switch valves.

Click here to register for RefComm® so you can check out what Bay Valve has to offer, along with dozens of other innovative companies. Once registered, you can download the RefComm® app to schedule an appointment with Bay Valve’s SW Regional Vice President Brad Fowler. For more information, visit Bay Valve’s website or contact Brad at bradf@bay-valve.com.

Leave a Reply

You must be logged in to post a comment.