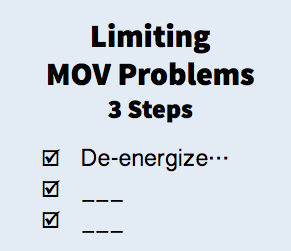

3 Steps to Limiting MOV Problems

ELECTRIC MOTOR OPERATED VALVE PROBLEMS have been well documented for many years, but still occur at most facilities far too often. There are solutions out there to almost all MOV problems, but it can be difficult to enact them due to cost, configuration, or culture.

We’d like to share with you three simple, inexpensive steps that should be in place on all Delayed Coker structures.

We’d like to share with you three simple, inexpensive steps that should be in place on all Delayed Coker structures.

We are polling the Refining Community to find out where the issues are with MOVs. From the survey results, we will recommend solutions, engage suppliers to deal with bad actors and develop better technologies.

After taking the survey, you will receive the link to Limiting MOV Problems.

Interlock logic can (and will) be bypassed, equipment will fail, operators won’t always be on top of their game. These three cheap and simple steps can play a significant role in minimizing the impact of problems.

Take the Survey

Leave a Reply

You must be logged in to post a comment.