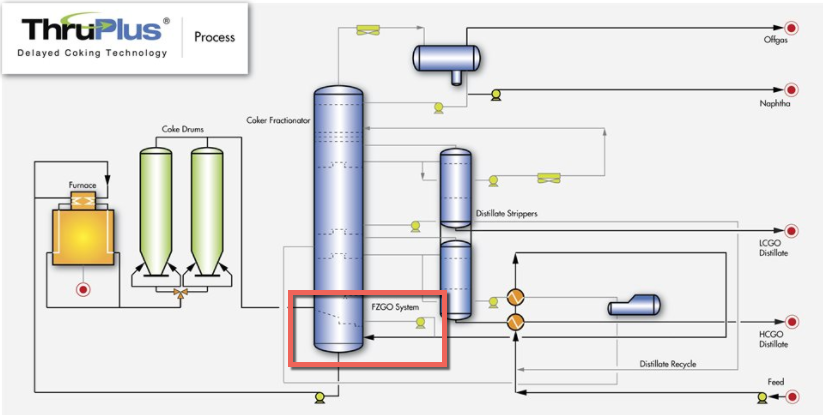

Check out the article in this month’s Hydrocarbon Processing (July 2017) entitled “Enhanced Flash Zone Design for Coker Fractionators” by Thomas, Spalding, Patel, and Varma from Bechtel (BHTS). It is the most clear revelation of some of the internals around the proprietary fractionator bottoms design by Bechtel, formerly owned by ConocoPhillips. This design aspect has been relatively top secret for many years. For those of us in the know (aka signed NDAs) or those who have COP/BHTS licensed units, this information is old hat for you. Remember the first rule of Fight Club, “you do not talk about the FZGO tray.” Seriously, if you have not been exposed to this technology, this article is worth a read.

Check out the article in this month’s Hydrocarbon Processing (July 2017) entitled “Enhanced Flash Zone Design for Coker Fractionators” by Thomas, Spalding, Patel, and Varma from Bechtel (BHTS). It is the most clear revelation of some of the internals around the proprietary fractionator bottoms design by Bechtel, formerly owned by ConocoPhillips. This design aspect has been relatively top secret for many years. For those of us in the know (aka signed NDAs) or those who have COP/BHTS licensed units, this information is old hat for you. Remember the first rule of Fight Club, “you do not talk about the FZGO tray.” Seriously, if you have not been exposed to this technology, this article is worth a read.

Let’s bring attention to a question raised by this design that is not addressed in the article. What to do with the FZGO material?

From a high level, the FZGO draw will have high end point, high solids (coke fines), high CCR, high asphaltenes, and high just about anything else downstream units do not like. The downstream disposition for this material can be a challenge but it is possible with proper design and planning to utilize it profitably.

Let’s address design first. Downstream of that draw, there obviously needs to be some filtration to get rid of the solids. Where this filtration should be located gets into another debate but we will save that for a future article. You might have a “split the flow” so that some of the material can be put back into the furnace charge as recycle or some mixed in with heavy coker gas oil (HCGO) as product or as a special FZGO product. (Side note: FZGO has one of the best nicknames for a coke product ever! Fuzzy Gas Oil.) Extra degrees of freedom are good for the operator and the control measures can be used over various elements in the tower bottom, furnace, drum, and product qualities. Ensuring the preheat exchangers and other downstream equipment can handle the high-everything material and flow variation is also critical. You definitely would not want to foul the preheat exchangers with solids after installation of this system.

Second point: planning how to manage this fluid. With extra degrees of freedom comes decisions. These decisions are internal (recycle vs. fresh feed) and external (FCC or HDC) to the coker. To truly maintain this scenario, finding the economic solution between coker and FCC/HDC rate and yields will make the most money for the plant. This is where we see sites make short term decisions without fully considering the upside benefits. Here is an example to illustrate my point. For a refinery where coker capacity limits crude capacity, resid (aka fresh feed) destruction is king, economically speaking. This means minimizing recycle as much as possible. To do this, all or most of the FZGO needs to go to OSBL of the coker for further processing. But this decision generally will hurt conversion/yields and increase hydrogen consumption in the CFHT or HDC. Many times, catalyst performance is seen as king in the refinery. We all know there cannot be two kings (see the popular HBO series, Game of Thrones, for proof.) The proper decision comes down to maximizing the profit for the entire plant (e.g. LP modeling) but often this trade-off is more delicate than the LP can handle. Therefore, the Cadillac units, oh I meant to say Catalytic units tend to win the debate in the absence of good system modeling.

Great article by Bechtel. Thanks for sharing the details of the trap out tray design. It brings into focus a secondary question of what to do with this material. It is very manageable but must be considered to get a full benefit to cost evaluation of this design.

Other Reads

http://www.bechtel.com/services/oil-gas-chemicals/bhts/delayed-coking/

Leave a Reply

You must be logged in to post a comment.