The Sad Life of Pressure Gauges

You know I keep seeing the re-occurring theme about pressure gauges  out in the unit every time I go to a plant, no matter if they’re top tier or bottom tier or middle tier. Why are the gauges always bad?

out in the unit every time I go to a plant, no matter if they’re top tier or bottom tier or middle tier. Why are the gauges always bad?

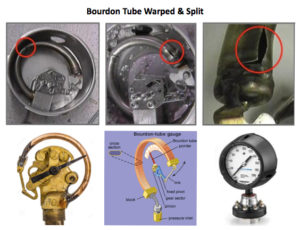

Do we understand that the gauge is actually just a little balloon hook through a branch connection to the process? It’s as close as we come to allowing the oil out of the pipe. When a gauge is bad, block it in and put a tag on it. Don’t just leave it going. Make sure that the root valve is closed down enough just to allow enough pressure to activate the gauge but not too much in case it does blow up.

I think it’s something that if you get four or five gauges that are bad maybe we need to have maintenance come out and change them. In your surveillance rounds, when you see gauges that are not operating properly, it’s definitely something we need to take care of and not just ignore.

I think it’s something that if you get four or five gauges that are bad maybe we need to have maintenance come out and change them. In your surveillance rounds, when you see gauges that are not operating properly, it’s definitely something we need to take care of and not just ignore.

Gauges are great for troubleshooting in the Coker, CatCracker, Sulfur and other process units. How do you know what levels may be in a tower above the process? How do you know what the discharge and suction pressure is on a pump? They’re very important and they need to be maintained. They need to be taken out of service if they’re bad.

-Gary Pitman Coker Subject Matter Expert, Refining Community

Get a Cold Eye Review of your equipment, procedures, processes and operations.

Leave a Reply

You must be logged in to post a comment.