Insulation is not installed just for the process.

A lot of people think of it as part of the process to keep liquid warm or to keep it from freezing. But a lot of the insulation is actually for personnel protection.

OSHA is very clear on its rulings about personnel protection. Anything under 70” and over 160f is to be covered for personnel protection. That doesn’t mean the insulation blanket is laying on the deck creating a tripping hazard. When insulation is removed it needs to be reinstalled in a timely fashion (not months or years later) it has an important purpose for the process or for personnel safety.

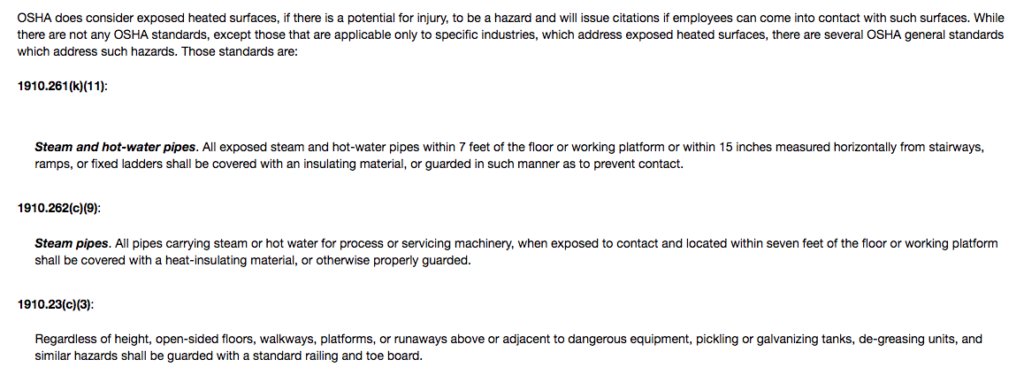

The ruling is very clear:

OSHA hazard standards for insulation and refinery safety

We work in an environment where the piping is a lot hotter than 160f. In some areas that have frequent maintenance I have seen heat shields or wired mesh that stands out from the piping to protect the personnel.

Refinery safety is paramount

Wherever we have to do routine work and we don’t have to hold the heat in, this wire mesh (above) makes more sense. It’s due diligence for operators that insulation be regarded and pursued as safety-related activity.

Keeping the unit free of insulation and post-construction debris is important for efficiency and profitability.

_________

For more coking and safety content, visit Gary’s Blog.

Connect with Gary on LinkedIn.

Leave a Reply

You must be logged in to post a comment.