This 3000 HP Westinghouse jet pump motor supported a 4 drum coker built in the early 1970s. The facilities’ Machine Vibration Group began to see elevated readings on the motor during their monthly critical motor route, and requested help from Instrumentation and Electrical (I&E) to determine the source of the problem.

I&E took on-line current signature readings on the motor while it was under full load, and saw obvious indication of rotor bar failure. They looked at the motor’s current signature history and realized the prior year’s reading showed rotor damage that had been overlooked. The earlier readings had been taken when current signature data capture was still new to the facility, and the technicians collecting the data were not well qualified to perform the analysis. Comparison to the latest data indicated the motor’s health had deteriorated significantly in the past year.

The facility did not have a drop-in spare jet pump motor, but did have an older motor that required significant base and cooling water piping mods it could use if necessary. The Coker was more than a year away from turnaround, and did not have a window long enough to pull the motor and have it inspected without a significant rate cut. It was critical to understand the extent of the damage and the likelihood of catastrophic failure during operation. Based on the current signature analysis, I&E was able to make recommendations with a fairly high level of confidence. The facility decided on a two pronged approach: order a new motor (10 month lead time), and run the motor continuously rather than shutting it down between drilling cycles as had been the practice. The hope was to slow the deterioration rate and avoid having to take the production hit required to install the older motor. Keeping the motor running through the minimum bypass for nearly a year was calculated to add about $200,000 to the electric bill, but was viewed as a worthwhile insurance policy. I&E and Vibration technicians began monitoring the motor on a weekly basis to provide up-to-date motor health monitoring and predictive trends in case the deterioration had not slowed.

This approach was successful. The existing motor lasted until turnaround, the new motor was installed, and baseline and periodic current signatures were captured on the new motor. No production was lost, and the facility gained extremely valuable expertise in on-line motor diagnostics. The original motor was sent out for inspection, and the diagnosis of faulty rotor bars was confirmed.

Rotor bar current anomalies caused by an increased resistance present as elevated pole pass sideband peaks and are identified at 3 levels:

>-54 db = Rotor good

-45 db = Caution, some rotor bar damage

-36 db = Severe, imminent failure possible

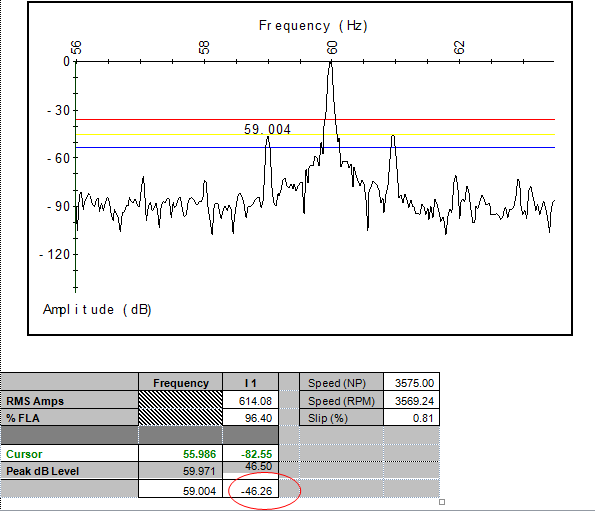

The first reading taken with a peak at -46 db, indicating rotor bar damage. This reading was not recognized as actionable by the technicians at the time. Improved training followed.

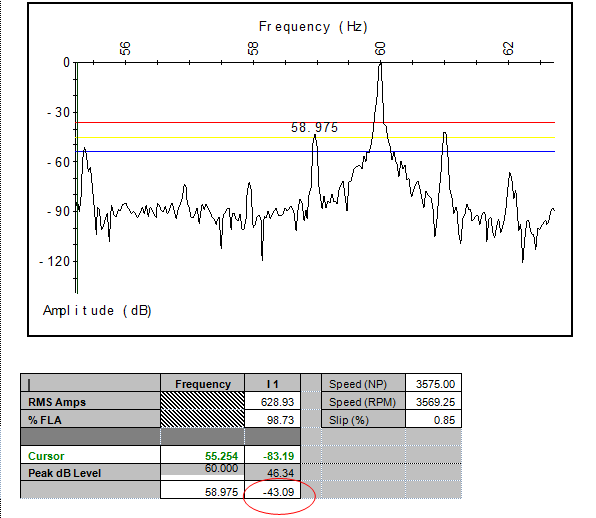

Pole pass spectrum taken in response to Vibration monitoring pointing to an electrical issue with the motor. It shows an increase of about -3 db compared to the prior year.

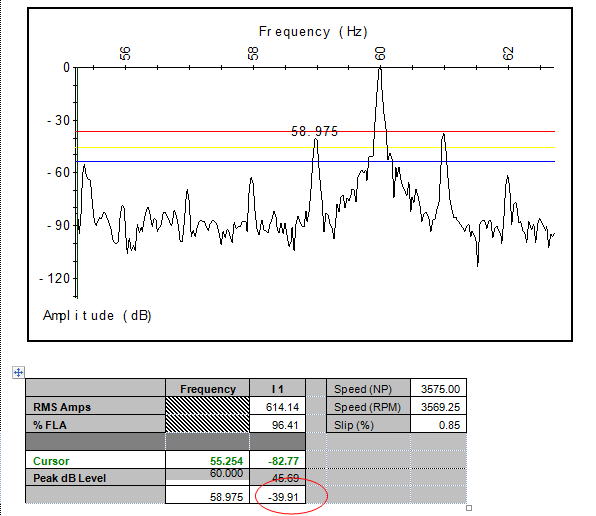

This reading was taken a month before shutting down the motor for replacement during the Coker turnaround. The motor had deteriorated another -3 db during the months of running.

The inspection by the motor shop showed 5 locations where rotor bar connections had cracked, several that were bent next to the end ring connection point, and serious overheating at multiple locations. Fortunately, form wound rotors are tough, and can handle a lot of damage while still performing their job.

Leave a Reply

You must be logged in to post a comment.