In Chicago politics, candidates sometimes prepare a red herring recipe to distract their constituents from deeper issues. With nearly half the municipal city council seats and mayor in jeopardy of losing their jobs in the looming Feb. 2015 election, taking action against fugitive dust from outdoor petroleum coke (petcoke) storage piles offers a tempting target.

Put simply, the petcoke industry — with few employees, located in contested voting districts and owned by demonized billionaires — is an easy dish for a politician to cook and serve.

Passed in December 2014, regulations now require petcoke and coal storage companies within the Chicago city limits to completely enclose operations due to complaints over excessive dust emissions. These rules are intended to drive ALL petcoke storage operations out of Chicago. This is not a matter of mere speculation; it’s a point of record.

According to Southeast Chicago Alderman John Pope, “Our continued efforts to kick petcoke out of our neighborhoods will ensure Chicagoans can be outside to enjoy their communities.” {1}

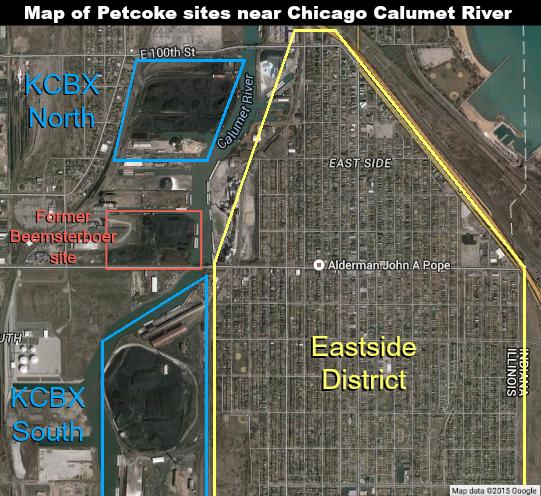

Prior to passing of the new legislation, political pressure and fines forced the closure of one petcoke storage facility in the Chicago area owned by Beemsterboer Slag Corp. However, the real target of these regulations is KCBX Terminals — a subsidiary of Koch Industries — and the company’s 82-acre outdoor facility along the Calumet River in Southeast Chicago. In the past, the facility has met all of the municipal air quality requirements in good faith, including the installation of a $10 million industrial sprinkler system to suppress dust. The system didn’t work as well as expected, but rather than allow the company time to review and test other outdoor dust suppression alternatives, local officials implemented the onerous regulations.

Following a denial of variance {2}, KCBX voiced its continued commitment to the Chicago area and submitted plans to build a $120 million enclosure on its existing site, measuring 1000′ long x 200′ wide x 100′ high (304.8m x 71m x 30.5m), by 2017. Creating 150 temporary jobs, the steel building would have 5,500 feet of enclosed conveyors. According to KCBX operations manager Mike Estadt, it would also feature a sprinkler-like dust suppressing system and its own water recycling system. Able to store up to 125,000 tons of bulk materials, Erstadt further stated that the bulk material would be covered from the time it arrives on trains to when it leaves by barge or truck {3}, thus fully adhering to the new rules.

However, the company’s agreement to these demands has caught the attention of stakeholders in the petcoke and coal industries from around the country, who are monitoring this issue closely. The main concerns are:

- This may set off a trend in other U.S. municipalities, resulting in the closure of dozens of smaller operators.

- By requiring an enclosed environment, companies are forced to adhere to stricter indoor air quality standards, running the potential risk of creating an unsafe workplace and leading to more fines and closures.

Welcome To The Regulation Dome

The regulations require: {4}

- Dust Prohibited [3.0 (2)(a)(b)] – No fugitive dust is allowed past the property line of the facility. No transfer point, roadway or parking areas may have dust equal to or greater than 10% opacity for a period aggregating more than three minutes in any one hour.

- Fully Enclosed Structures [3.0 (4)] – The owner or operator of a facility shall maintain all bulk solid materials in fully enclosed structures.

- Dust Suppression [3.0 (6)(h)] – Operator must apply chemical stabilizers and/or maintain and operate water spray bars, a misting system, water spray systems and/or water trucks to control fugitive dust emissions.

- Runoff [3.0 (6)(i)] – Operator shall install and maintain stormwater management, erosion and sediment controls to prevent runoff from the pile onto neighboring parcels, the right of way, any water bodies, or into groundwater or the public sewers.

- Conveyors [3.0 (13)] – All conveyors shall be enclosed.

- Transfer [3.0 (14)] – All transfer points shall be totally enclosed. Doors may not remain open during material transfer onto transport.

- Transportation [3.0 (7,8,9)] Trucks shall be loaded within the enclosed space. Barges and trains loaded by enclosed conveyor system. All loads must be covered completely for zero loss.

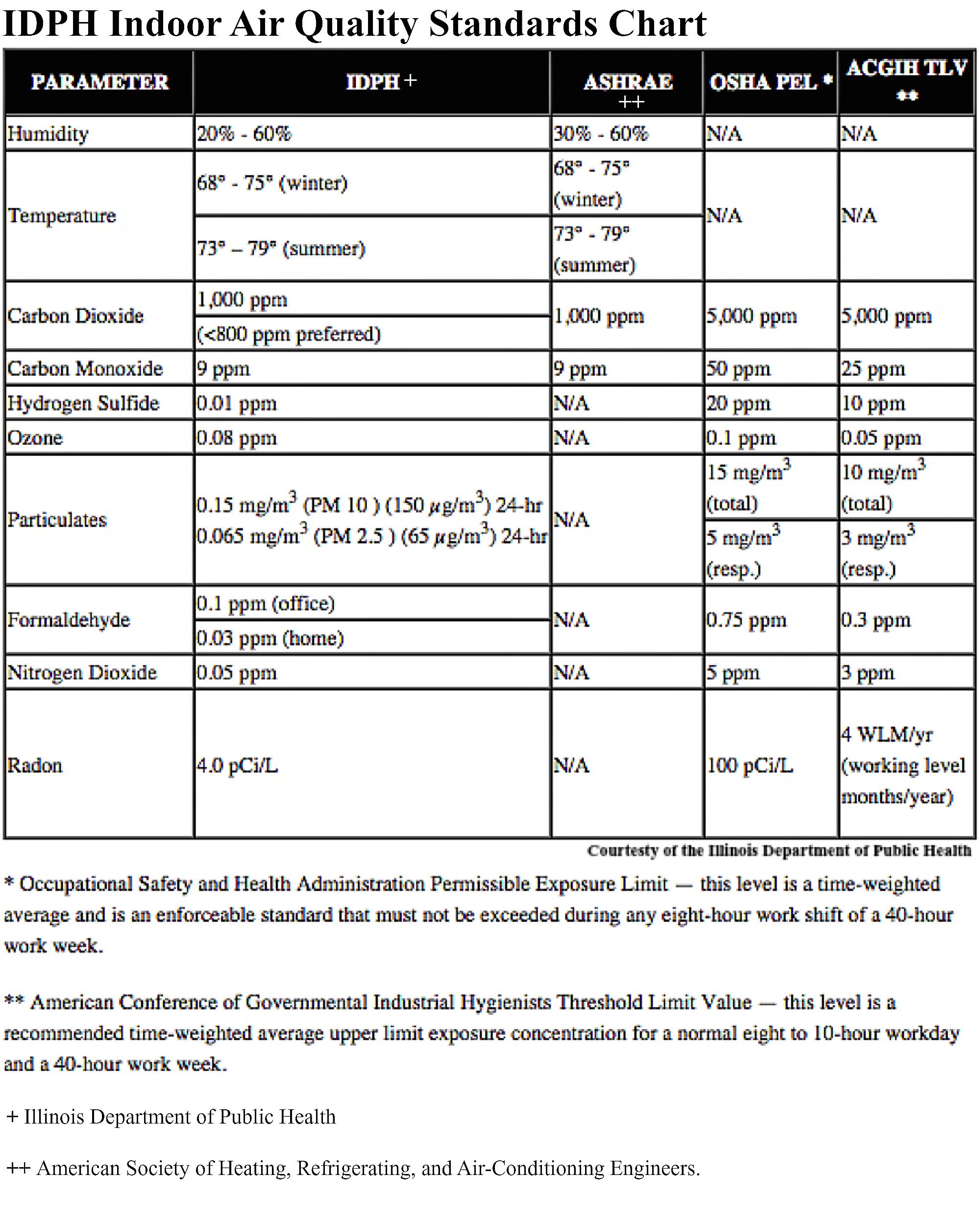

What advocates of the new regulations failed to address is the creation of a potentially unsafe workplace. The indoor standards state:

“The [Illinois] Department [of Public Health] recommends that particulates 2.5 micrometers to 10 micrometers in diameter (PM10) be maintained at less than the USEPA National Ambient Air Quality Standard (NAAQS) of 150 micrograms of particulates per cubic meter of air (ug/m3) and particulates 2.5 micrometers in diameter or less (PM2.5) be maintained at less than the NAAQS of 65 ug/m3 during a 24-hour time period.” {5}

This means that the company must install a state-of-the-art ventilation system capable of clearing the air, filtering the vast majority of the ventilated particulates. Further, since trucks need to be loaded within the enclosed space, with no doors open during loading, CO2 emissions compound the air quality issues, as demonstrated by the chart below: {5}

Creating a Safe Work Environment

For an open warehouse that is expected to be as much as 20 million cubic feet, industrial air ventilation systems may be able to address CO2 emissions, but will not be able to adequately control dust. Neither will a sprinkler system. Even with the use of non-hazardous chemical aids such as surfactants {6}, sprinklers use a tremendous amount of water and only treat surface material, without eliminating dust from the air. Due to their average size of 500 to 10,000 microns, {7} sprinkler droplets create a slipstream that can cause the smaller dust particles of 50 – 200 microns {7} to move around them, thus offering very limited suppression of airborne dust. Surface treatment alone does not eliminate dust, since the product is frequently in a state of disruption.

In addition, a single sprinkler can use up to 500 gallons per minute (GPM) (1,893 LPM) of water to achieve surface area coverage. Even with runoff systems in place, this water can drain onto floors, creating a potentially hazardous surface for workers to walk on.

However, the rules also suggest that a mist may be used. With droplets of just 50-200 microns in size, atomized mist has been proven to effectively contact fugitive airborne particles and harmlessly pull them out of the air. Propelled by a powerful electric fan with 359-degree oscillation, a single unit can cover as much as 280,000 square feet (26,013 square meters) of area. Atomized misting technology also averages a fraction of the water usage, with even the largest units applying just 25.5 GPM (96.5 LPM) at 80 PSI (5.5 bar). With a chemical additive, this method offers superior dust suppression and surface coverage, with drastically reduced water usage.

If atomized mist technology is used in tandem with an appropriately-engineered air ventilation system, KCBX may be able to comply with the indoor air quality standards set by the Illinois Department of Public Health. Perhaps more significant, some petcoke facilities are finding that the outdoor use of atomized misting systems may be a sufficient means of dust management to prevent the need for such devastating enclosure regulations.

Regulation Domino Effect

The largest concern for many coal handlers, petcoke storage companies and other dust producing bulk-handling operations is that the onerous regulations may become a nationwide trend. If the largest player in the petcoke industry succumbs to the political pressure from special interest groups, there may be very little that smaller operations can do to stop other localized entities from adopting the language in these rules and implementing similar restrictions in their own areas.

In the war on dust, petcoke is quickly becoming a casualty, not just in Chicago, but nationally. Though shown to be inert and harmless to the environment {8}, as well as being labeled a non-toxic internationally-traded commodity, the U.S. Environmental Protection Agency considers petcoke a pollutant. With modern dust control technology as a potential alternative to expensive enclosures, it is imperative that legislators — local, state and national — put politics aside and consider whether there may be other suppression choices to prevent crippling this important American industry.

References

{1} Chicago Mayoral Press Office, “Mayor Rahm Emanuel Announces Latest Efforts to Crack Down on Harmful Petcoke Emissions”, Press Release, December 10, 2014.

{2} Coucair, Bechara, Commissioner M.D., “KCBX Terminals Company’s Petition for Variance; Letter to Stephen Swedlow, Quinn Emanuel Urquhart & Sullivan, LLP”, City of Chicago Department of Public Health, December 9, 2015.

{3} Pete, Joseph S., “KCBX to build $120 million petcoke enclosure”, Northwest Indiana Times, Dec. 16, 2014.

{4} Coucair, Bechara, Commissioner M.D., “Article II, Air Pollution Control Rules and Regulations For Bulk Handling Storage Material Piles”, City of Chicago Department of Public Health, March 13, 2015.

{5} Staff, “Environmental Health Fact Sheet: Illinois Department of Public Health Guidelines for Indoor Air Quality”, Illinois Department of Public Health, May 11, 2011.

{6} Irwin, Karen, “Testing of Dust Suppressants for Water Quality Impacts”, U.S. Environmental Protection Agency, Sept. 2008.

{7} Staff, “Particles: Size Makes All The Difference”, National Institute of Environmental Health Services. Feb. 2006.

{8} Mckee, Richard H., Deborah Herron, et al, “Toxicological Assessment of Green Petroleum Coke”, International Journal of Toxicology, January/February 2014 vol. 33 no. 1 suppl 156S-167S.

Leave a Reply

You must be logged in to post a comment.