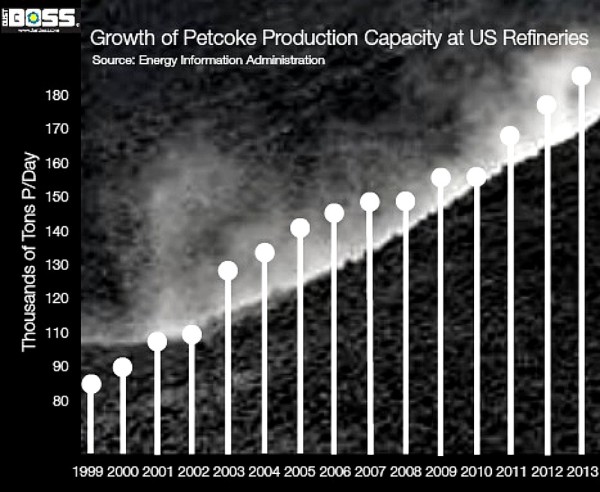

Petroleum coke (petcoke) production and supplies are on the rise, introducing environmental and legal disputes between the largest handlers of the material and the communities in which it is transported and stored. The controversy is over the potential for air and water pollution, including the manner in which the industry engages in petcoke dust suppression and the subsequent runoff control. The growing mountains of petcoke are largely attributed to expanding tar sands production and the refining process of which the material is a byproduct. Since 1999, according to the Energy Information Administration (EIA) , the amount of petcoke produced has more than doubled, currently reaching about 180,000 tons per day.

It is used for various industrial applications such as calcination, cement, and fuel, although the EPA has stopped issuing new permits for petcoke use as a fuel in the U.S. Foreign markets such as China and India purchase petcoke by the shipload, creating a strong demand for the product. But storage and transport from production to export are still major issues — particularly in the U.S. — due to fugitive dust and water runoff.

It is used for various industrial applications such as calcination, cement, and fuel, although the EPA has stopped issuing new permits for petcoke use as a fuel in the U.S. Foreign markets such as China and India purchase petcoke by the shipload, creating a strong demand for the product. But storage and transport from production to export are still major issues — particularly in the U.S. — due to fugitive dust and water runoff.

Tighter Regulations, More Scrutiny

As local and regional authorities impose tighter regulations on petcoke handlers, facilities across the nation are looking for better control methods to manage fugitive dust. In some locations, new regulations require facilities that store petcoke, coal, and other forms of coke to fully enclose their storage piles — a complex and expensive approach. In most areas, local residents have also become much more aware of the ongoing discussions about dust and its potential effects, and many have begun voicing those opinions strongly in public. After researching best-practice options, some facilities have concluded that large sprinkler-type irrigation systems are the only practical alternative to manual spraying of stockpiles with a fire hose. Unfortunately, these sprinklers are typically expensive and use large quantities of water, which can create other issues.

Can Sprinkler Systems Solve the Dust Problem?

There are three main reasons why sprinkler systems may not be the optimal method of dust control in petcoke applications: droplet size, water volume, and environmental exposure.

Droplet Size – Water shot at high pressure through these large nozzles typically causes droplets to form into sizes ranging from approx. 2-6 mm (2000-6000 microns). Most petcoke dust particles are much smaller: less than 100 microns. Due to the size of the water droplet, the effect of landing on dry dust can cause particles to become airborne, rather than keeping them place. For optimum dust suppression, water droplets need to be the approximate size of the particle, with a smaller impact to properly absorb them, causing them to agglomerate and fall to the ground. That’s what makes atomized dust suppression systems (generally with droplets in the 50 – 200 micron size range) so much more effective. Though sprinklers do provide some misting action — with droplets as small as 200 microns — their intent is to wet the surface of the pile, not control the airborne dust around it. Airborne particles that approach large droplets can experience a “slipstream effect,” in which the mass and velocity of the droplet produce an airflow around it, rather than absorbing the particle. In contrast, atomized dust suppression systems create droplets small enough to settle more slowly and moisten the surface of the pile without kicking up dust. The atomized droplets are also light enough to react to atmospheric airflow in a similar manner to particles, with the hang time required to travel with the flow of material and induce more droplet-particle collisions. Due to the larger volume of smaller sized airborne droplets, they have a better chance of encountering and absorbing fugitive dust particles and pulling them to the ground for effective airborne particulate suppression. In fact, atomized mist has so far been the only technology demonstrated as capable of suppressing both surface dust and airborne particles.

Water Volume – There is such a thing as too much water in petcoke applications, and sprinklers have been estimated to use as much as 30 times more water than atomized dust suppression systems. The problem is three-fold. Oversaturation causes petcoke to harden, making it harder to transport and process. Wet petcoke can also affect the market price. Once the moisture content is above 8%, the price fluctuates downward.

Environmental Exposure – Too much water can also lead to runoff, which not only means product loss, but potential leaching into soil and water tables that can raise environmental concerns. According to a study sponsored by the oil industry and published in the International Journal of Toxicology, petcoke — both airborne and runoff — has little effect on animals, plants and water quality. However, many experts (including the EPA and the State of Illinois lawsuit) hold different opinions, and the effects of large-scale sprinklers are at the center of the debate.

What’s the Optimum Solution?

Petcoke handlers continue to investigate potential solutions to the dust management issue, as industry experts seek ways to further improve regulatory compliance and environmental reputation, as well as save money in product loss, saturation concerns, legal costs, and possible fines. Some firms are finding that atomized mist technology is a more effective and sensible long-term approach to dust suppression than high-volume water spraying. Petcoke operations have similar dust issues to coal and demolition companies, and leading suppression equipment suppliers that have had excellent success in those industries are beginning to apply the same science of an “engineered mist” to petcoke applications. One of the most effective methods thus far is a family of high-powered ducted fan designs with brass atomizing spray nozzles, which can project an atomized plume of tiny water droplets more than 100 meters (328 feet). The largest model can blanket as much as 280,000 square feet from a single location. They can be mounted on fixed poles for expanded coverage and precise aiming, but large operations may opt to keep one or more machines on mobile carriages, so site managers can easily adjust to changing wind patterns.  Atomization is not a new technology, but only in the last few decades has it been widely applied for industrial dust suppression. The new generation of designs is engineered specifically for particle management, and some suppliers can even customize their units for specific operations and conditions. So far, petcoke handlers have experienced a significant improvement in air quality and runoff by using atomized mist instead of high-pressure sprinklers. Air monitoring data is currently being collected at several sites to help quantify the gains. While it’s likely that no single dust management technique will provide the level of control sought by critics and concerned citizens, it’s hoped that the technology may be recognized as having meaningful benefit to petcoke handlers and residents who live near those operations, eventually becoming part of an effective solution plan.

Atomization is not a new technology, but only in the last few decades has it been widely applied for industrial dust suppression. The new generation of designs is engineered specifically for particle management, and some suppliers can even customize their units for specific operations and conditions. So far, petcoke handlers have experienced a significant improvement in air quality and runoff by using atomized mist instead of high-pressure sprinklers. Air monitoring data is currently being collected at several sites to help quantify the gains. While it’s likely that no single dust management technique will provide the level of control sought by critics and concerned citizens, it’s hoped that the technology may be recognized as having meaningful benefit to petcoke handlers and residents who live near those operations, eventually becoming part of an effective solution plan.

Leave a Reply

You must be logged in to post a comment.