Boots on the Ground Series

Hi folks, it’s time for another safety check. The story I am going to share is about a plant visit I conducted many years ago at a refinery that will remain unnamed.

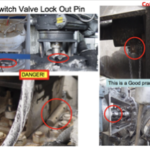

I was actually invited to this particular plant to inspect their plans for egress pathways on the top deck. As I am being lead to the deck by a refinery worker (we’ll call him Ron), I see a four-drum coker with two switch valves. Standard stuff, right? Well as I look closer, I can see there are switch valve lockout pins lying on the valve bonnet.

“Why are the lockout pins lying here on the bonnet and not installed?” I ask Ron.

“Do you mean the shipping pins?” he responds.

“No, those are definitely the safety lockout pins,” I inform him.

“Oh no,” Ron assures me, “those are the shipping pins.”

I press further. “No. Those pins right there are to keep the valve from going into the bypass position!”

Ron calls Coordinator Bob to verify. I can hear Bob’s response over the phone. “What the heck is he talking about? Get him down here now!” And I am thinking, oh boy, here we go!

lockout pin

When we got to Bob’s office, every operator, unit manager, and engineer from the coker is standing there ready to rip me a new one. They really thought I didn’t know what I was talking about and here they had just hired me for some rather expensive safety improvement work.

The manager was clearly annoyed with me and the room was starting to get a little hot. Suddenly, an idea occurs. “Let’s call the valve manufacturer and ask him,” I suggest. And thank god he answered.

The valve manufacturer confirmed exactly what I had been saying and as he explains how the lockout pins work to us on speakerphone, Coordinator Bob is glaring at me, his face getting redder and redder by the minute.

“The pins allow the valve only to go from Drum A to B, from D to C, or whatever the combo is,” the valve manufacturer is saying. “It keeps the switch valve from going to the bypass position, unless you want it to. In other words, it keeps you from deadheading the cracked resid flow which can plug up the heater or blowout a gasket. ”

This unit coordinator is spitting mad at this point. Someone had told him those were shipping pins and that’s how he had trained his team for years on end. He runs into his office and slams the door. And while I didn’t want to gloat that I was right, it did feel a little bit good to be vindicated.

They put the safety safety pins back in both switch valves, and three weeks later they had what we in the industry call a “fugitive movement.” But thankfully, no damage was done because those pins were right where they were supposed to be.

“You saved us millions,” a friend from that plant later told me.

In my 40+ years of working in refineries, I have inspected more than 100 cokers and 50% of the time, I see the safety lockout pins are out. When the unit starts up and they have to go to bypass, they don’t put them back in. The risk is that the valve could go to the bypass line 3rd port. If the line is not prepared for that, (in other words, if it wasn’t your intention), you end up plugging the flow and blocking the heater, or worse.

These motors are extremely powerful. The chance of a fugitive movement– something electronically going a little bonkers– is not that rare. It happens. Somehow it gets a missed signal or the valve drifts. And then it’s out of our hands. The size of the shaft is five or six inches. Nothing’s gonna stop it– it’s a big motor! That’s why the pins are so robust and so very important.

A Case of Mistaken Identity

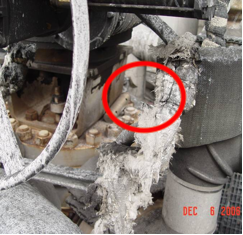

Here are some additional photos of safety pins mistaken for shipping pins:

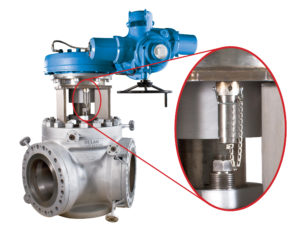

I recently checked in with the industrial valve manufacturer Velan to put some perspective on this issue. Their coker switch valves are supplied with mechanical jammer pins to prevent accidental rotation to the bypass port. The Velan pins need to be retracted for startup and shutdown operations, when the valve is positioned to bypass.

Afterwards, once the valve has been stroked from bypass to one of the drum ports during startup, the jammer pins need to be reinserted. During shutdown, the jammer pins are retracted before initiating the stroke to bypass. The jammer assembly is rated to withstand full actuator output torque. They supplied an OEM picture which clearly shows the safety jammer pin:

Velan coker safety jammer pin

Many refinery operators aren’t as aware about them as they should be. But now you know! Check that those switch valve lockout pins are where they’re supposed to be and prevent costly equipment malfunction.

Maximize your refinery production with less risk. Get an onsite Cold Eye Review of your equipment, procedures, processes and operations from the experts at Coking.com Inc.

Leave a Reply

You must be logged in to post a comment.